World’s Most Sensitive Distributed Acoustic Sensing System

picoDAS is the best-in-class fiber optic distributed acoustic sensing (DAS) system, featuring patented technology for superior performance. It offers not only the highest sensitivity, but also response uniformity including being free of sensitivity deterioration along the entire sensing range. Moreover, this product is the only DAS system that does not exhibit any cross-sensitivity between channels. picoDAS has been field proven since 2018 for its long-term reliability and exceptional ability to detect extremely weak acoustic events, such as micro-seismic emissions below the detection thresholds of other DAS products.

Key Features

- Best-in-class sensitivity

- Channel-to-channel response uniformity

- No cross-sensitivity between channels

- No sensitivity deterioration across the fiber

Typical Applications

- Structural health monitoring

- Vertical seismic profiling

- Micro-seismic event detection

- Well flow and integrity

- Pipeline leak detection

- Perimeter security

Technical Specifications

Details

| Model | picoDAS |

| Spatial Resolution | 2m or 5m or custom |

| Maximum Sensing Range | 5km plus up to 15km lead fiber |

| Sampling Rate | 15-125kHz |

| Sensitivity | <0.15nϵ typical, <0.5nϵ max |

| Sensitivity Disparity | <20% |

| Interrogator Dimensions and Weight | 27x45x44cm, 17.3kg |

| Computer Interface | Ethernet |

| Power | 240/110V, 50/60Hz |

| Power Consumption | 82W Max |

| Operating Temperature | 0 to 45oC |

| Humidity | 5-95% |

| Fiber Connector | FC/APC or E-2000/APC |

Special Software Features

Details

picoDAS is equipped with powerful software that offers real-time 3-D display of acoustic waves at each position of the sensing fiber. The 3-D graph can be freely rotated and adjusted in display scale. Data storage can be synchronized by external trigger or set by a predetermined threshold of the acoustic amplitude. The software provides various digital signal processing and analysis. Additionally, data can be downsampled after filtering to significantly decrease storage demands while avoiding inadvertently aliasing noise into the frequency range of interest. This gives the noise-reducing capabilities of a high sampling frequency combined with the data size of a low sampling frequency.

Various output data formats can be provided per custom request. They may include the Hierarchical Data Format version 5 (HDF5) and the Production Markup Language (PRODML).

Relevant Data

Details

picoDAS has been tested extensively both in laboratories and in the field. The results have demonstrated the system’s superior performance and long-term field use reliability since 2018.

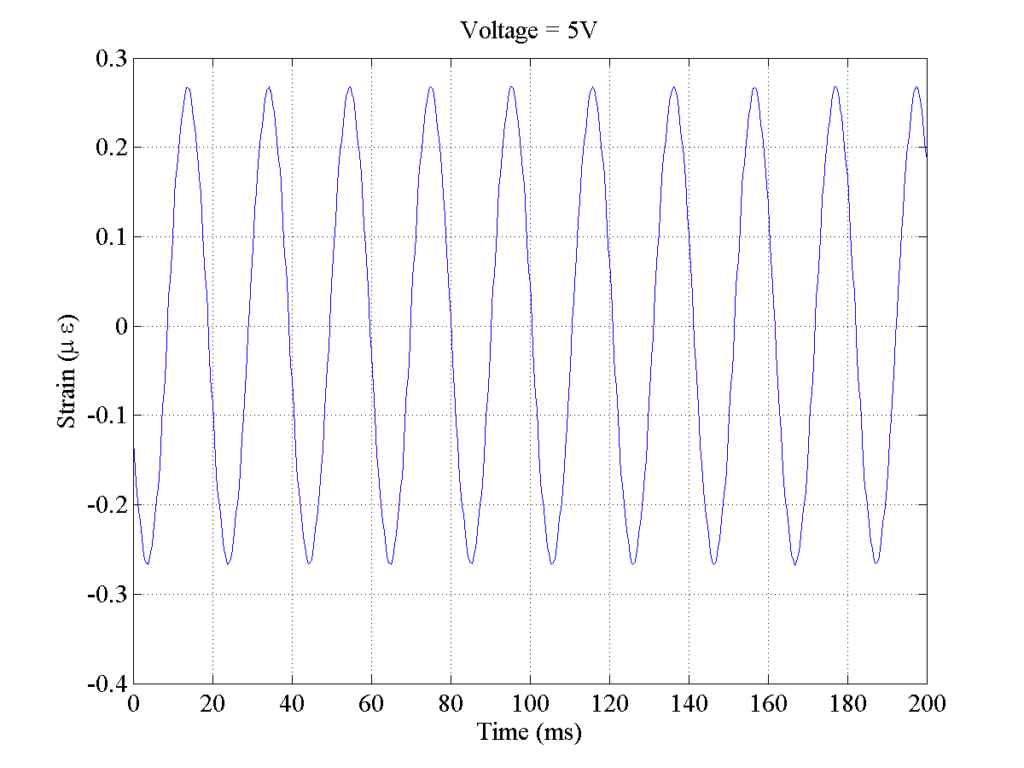

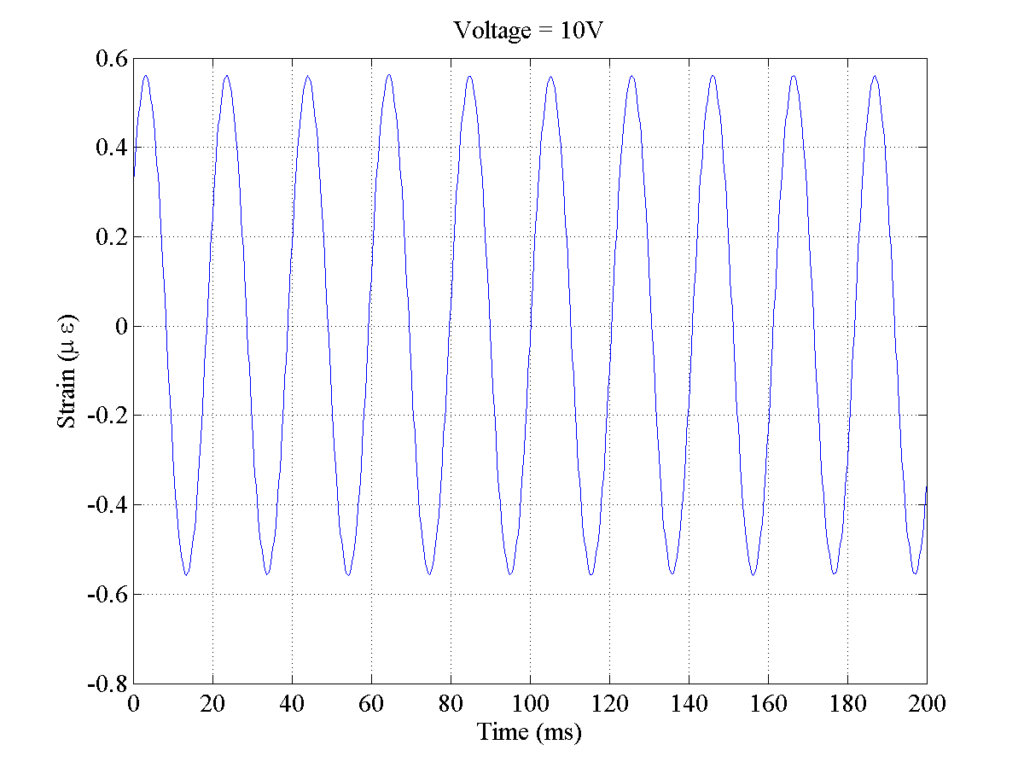

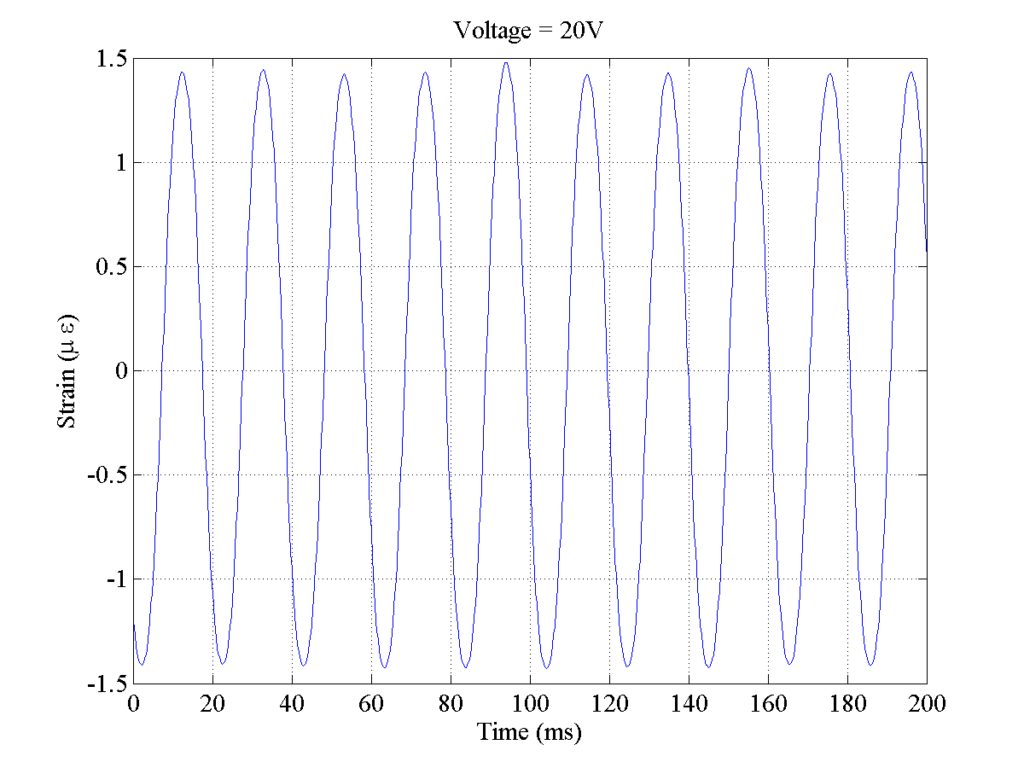

In one example of a performance evaluation, the system is tested by wrapping one channel of fiber on a piezoelectric cylinder that is driven by a function generator with varying sine wave amplitude. Figure 1 shows the picoDAS output in units of fiber strain for different driving signal amplitudes. The results show that the output is proportional to the applied voltage with an excellent linearity and signal fidelity. The spurious free dynamic range (SFDR) exceeds 20dB. This harmonic-free acoustic detection is especially important to applications such as downhole vertical seismic profiling (VSP), where an extremely clean signal response is highly desired.

Figure 1. picoDAS responses to fiber dynamic strain produced by a piezoelectric cylinder, which show excellent response linearity and signal detection fidelity. More importantly, such response is offered by every section of the entire 5km sensing fiber with the same acoustic detection sensitivity, linearity and fidelity.

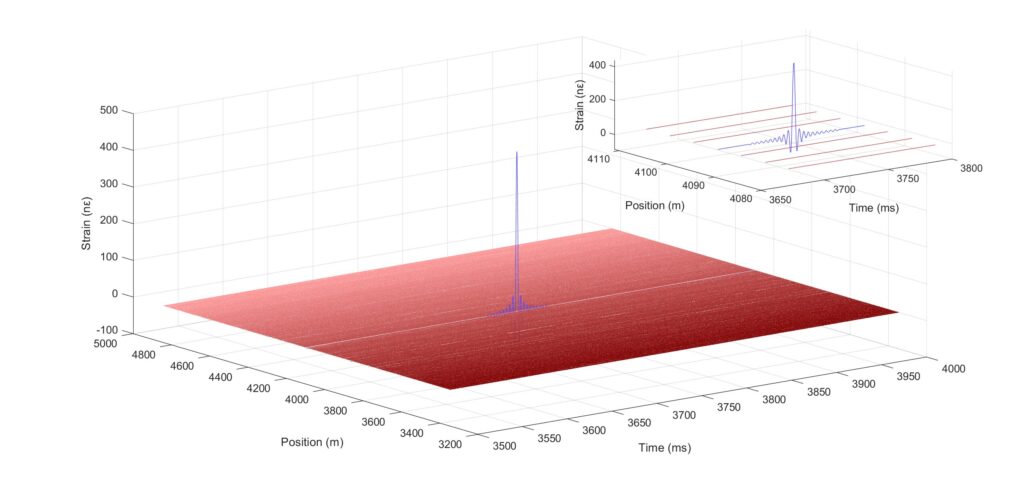

Figure 2 shows real measurement data from a 5km sensing fiber that is interrogated by picoDAS with 5m spatial resolution. The red color ‘carpet’-like plane comprises 360 sensor output lines as part of the 1,000 outputs. All these lines exhibit nearly identical noise floors within ±20% around the mean value (0.16nϵ). A 4.95m fiber segment at 4.2km position is wrapped on a piezoelectric cylinder, which is driven by a function generator to produce an impulse stretch to the fiber. The output of this fiber segment is given in the blue trace, which demonstrates high-frequency and high-fidelity response with no cross-sensitivity from the neighboring sensing fibers.

Figure 2. Measurement of channel-to-channel sensitivity uniformity over the entire 5km sensing fiber. Besides clearly demonstrating the system’s extremely high sensitivity, the result also exhibits zero cross-sensitivity as shown in the inset between neighboring sensing channels.

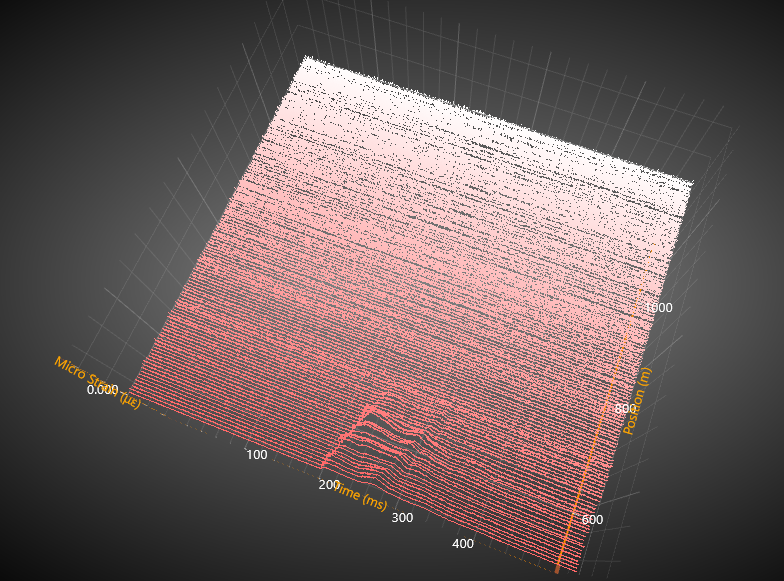

Figure 3. picoDAS has been deployed in various wells for micro-seismic event detection. Given its exceptionally high sensitivity, successful detection can be achieved with the fiber cable either in the cement surrounding the well casing or in the borehole. The graph on the left presents one example of a micro-seismic event successfully detected with a high signal quality. This detection was performed with the fiber cable in the bore filled mostly with water. This achievement is special because the weak signal is significantly attenuated by the well casing already. The high-quality data clearly shows picoDAS suitability for downhole measurement of acoustic waves including those that cannot be detected by other DAS systems.