NovaPT™-E 1500°C Engine Pressure and Temperature Sensing System Requires No Standoff Tube, Reducing Signal Distortion

NovaPT™-E from Sentek Instrument offers the highest temperature rating (1500°C) available commercially. The patented design of the optical pressure and temperature sensor offers multiple measurement readings in one, compact, rugged sensor. Sensing functions include dynamic pressure, static pressure, temperature, and multiple spatially separated temperatures. Interrogator and software options from Sentek Instrument allow users to unlock any or all of these intrinsic measurement functions from the same sensor probe. Up to 16 sensors can be monitored simultaneously. Eye-safe, near-infrared light enables long-distance fiber optic signal transmission without distorting dynamic pressure signals.

Key Features

- Reliable operation at 1000°C continuous; 1500°C intermittent

- Compact 3.75mm sensor tip

- High-frequency response up to 60kHz

- No need for sensor cooling or standoff tubes

- Resistant to EMI, corrosion, thermal shock, and neutron radiation

- Fully passive — No on-site power required

- Long-distance fiber optic signal transmission

Ideal For

- Gas turbine engines (conventional & unconventional)

- Advanced electric power generation systems

- High-temperature industrial processes

- High-temperature chemical processes

- Laboratory R&D applications

Technical Specifications

Details

| SENSOR | ||

| Model | NovaPT™-E600 | NovaPT™-E4000 |

| Maximum Static Pressure | 40bars (580psi) | 250bars (3,626psi) |

| Diaphragm Resonance Frequency | 400kHz | 1MHz |

| Sensor Tip Diameter | 3.75mm | |

| Combined Non-linearity, Hysteresis and Repeatability | <1% F.S. | |

| Maximum Sensor Tip Temperature | 1000oC (1832oF) for continuous use, 1500oC (2732oF) for pulse temperature | |

| Installation Thread | M7x1.0 | |

| Fiber Cable Length | 0.5m 150oC rated fiber cable; 3, 15 or 50m extension cable option available | |

| INTERROGATOR | |||

| Model | Fasedyne-1000 | Fasedyne-2000 | Fasedyne-3000 |

| Measurement | Dynamic Pressure | ||

| Frequency Response | 20-4,000Hz | 20-25,000Hz | 20-60,000Hz |

| Resolution (1σ) Maximum Static Pressure Rating | <0.01% | <0.02% | <0.02% |

| Sampling Rate | 27kHz | 50kHz | 120kHz |

| Sensor Channels | 1, 2 or custom | 1, 2 or custom | 1 only |

| Dimensions | 26x108x180mm, 1 or 2 channels310x220x120mm, 4, 8 and 16 channels | ||

| Power Supply and Consumption | 12VDC, 4W | ||

| Digital Output | USB Micro-B | ||

| Analog Output (Optional) | SMA, Hi-Z, 0-5V | ||

| Trigger Input | SMA, 50Ω, 10V (Max) | ||

| Environmental Conditions | -10 to 45oC, 5-90% humidity | ||

| Software | Flexible data display, storage control or spectrum analysis (Fasedyne only) | ||

Sensor Probe

Details

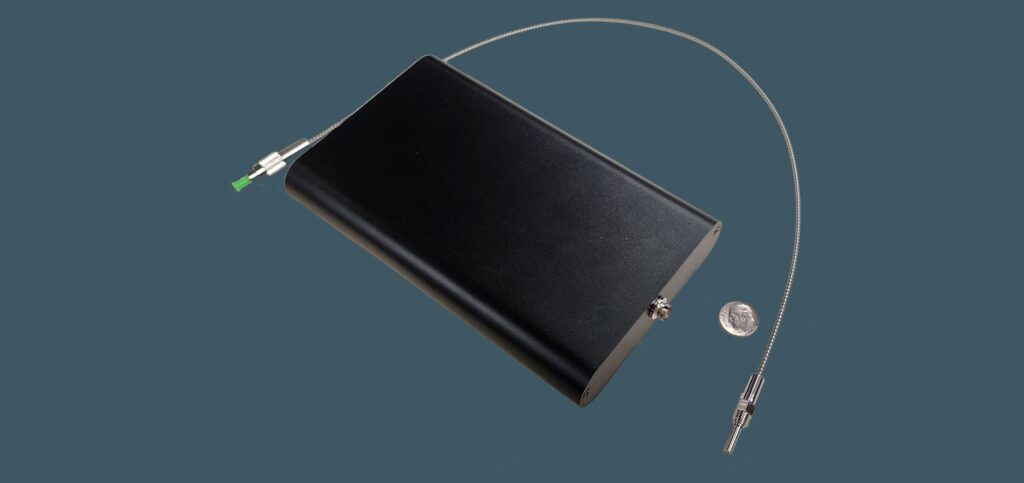

The NovaPT™-E sensor is packaged in a metal housing that is oxidation- and corrosion-resistant, and has a 3.75mm tip diameter as shown in the drawing below. The standard M7x1.0mm mounting thread with a metal crush seal ring as shown in the schematic drawing below makes the sensor installation simple, easy and reliable. The maximum service temperature of the sensor is rated for 1000oC for continuous use and for 1500oC for pulse temperature or limited time use. Higher service temperatures can be available by custom order. Smaller form factors can also be customized to accommodate special application needs.

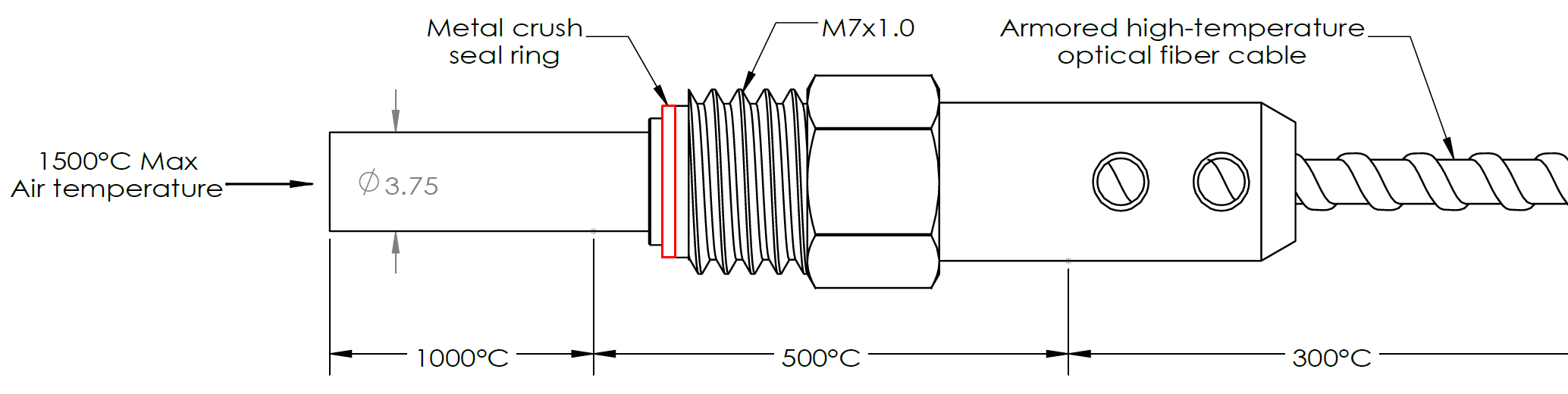

Sensor Interrogators and Software

Details

The NovaPT™-E sensor intrinsically offers multiple measurement functions including dynamic pressure, static pressure, temperature and even multiple temperatures at different sensor axial positions. These functions can be unlocked by the use of different sensor interrogator options without any need for sensor modifications or fiber cable changes.

|  |

| Interrogator rear panel view | Graphical user interface |

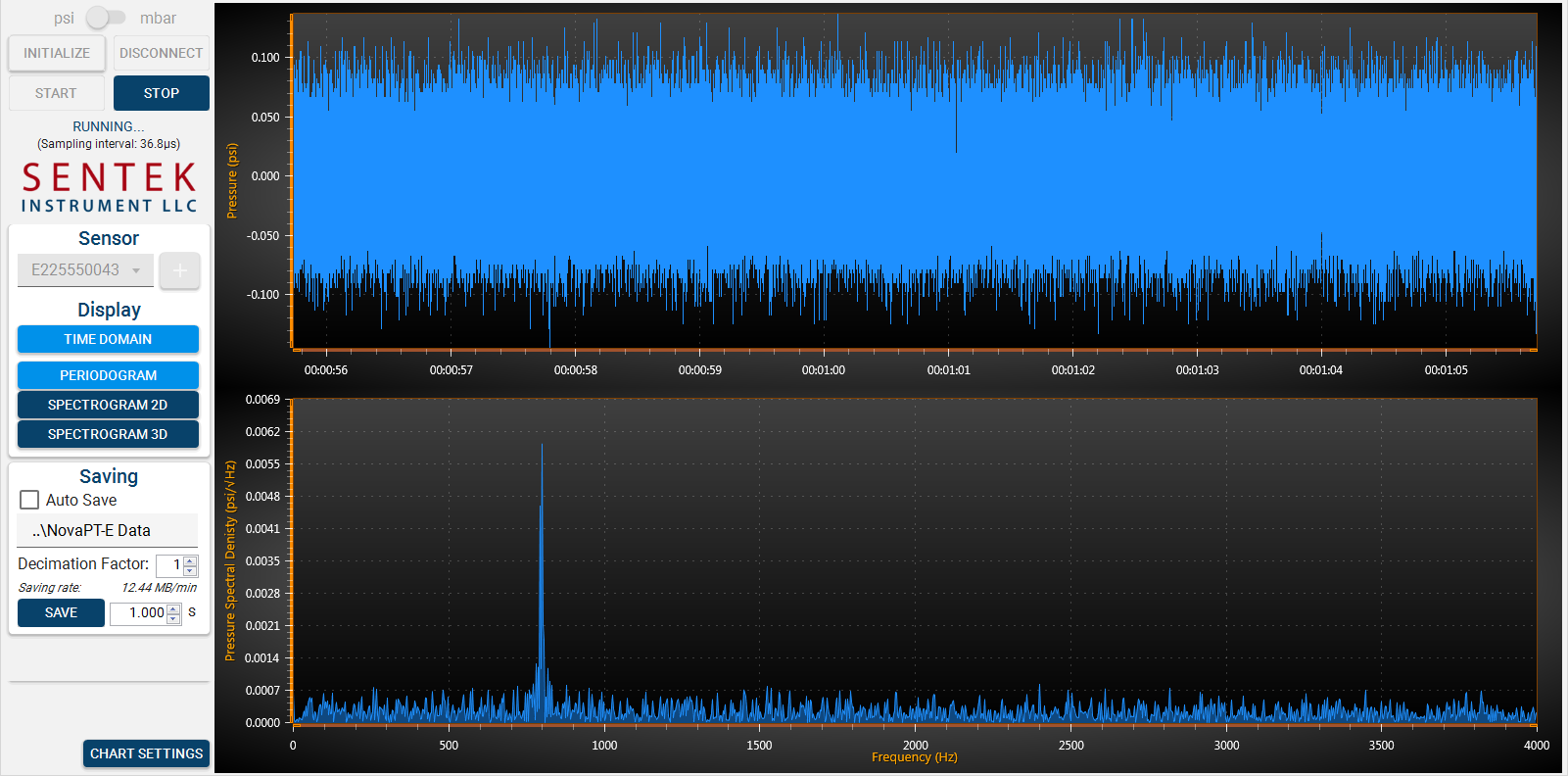

The Fasedyne is an interrogator for dynamic pressure measurement. This compact interrogator along with the NovaPT™-E is designed to meet the increasing market demand for dynamic pressure measurement directly at ultrahigh temperatures without the need for a standoff tube or water cooling. The miniature sensor probe permits measurement in space-constrained areas without distortions to the dynamic pressure signals. The interrogator provides both 0-5V analog and digital outputs. This compact size, light weight, and low power consumption interrogator can also be upgraded to work in 125oC environment and offers a great potential for its integration into full authority engine control (FADEC) units of flight engines. The Fasedyne interrogator comes with a graphical user interface (GUI) that allows the user to display and analyze the pressure signals from the interrogator in real time on an external PC. Besides the temporal pressure traces, the user can choose to display the Discrete Fourier Transform (DFT) for any single screenshot or as a function of time, as displayed in either waterfall or 3-D graphics.

Sentek can also offer additional specially designed interrogators to further unlock the other intrinsic measurement functionalities offered by the NovaPT™-E sensor. These interrogators need to be custom ordered for measurement of static pressure, temperature, and multiple temperatures for deduction of other quantities such as heat flux.

Relevant Data

Details

SENSORS

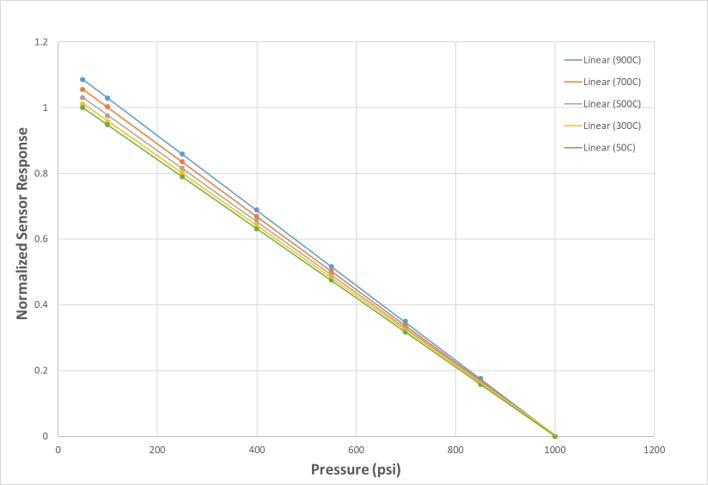

NovaPT™-E sensing transduction is realized by the optical measurement of the deflection of a single-crystal sapphire pressure diaphragm. The diaphragm deflection is temperature dependent due to the thermal dependence of sapphire mechanical characteristics – mainly the Young’s modulus. This dependence is evaluated by measurement of the sensor response to pressure under different temperatures. The temperature coefficient of pressure measurement is measured to be 0.010% reading point/°C for measured temperatures up to 900°C. Sapphire’s Young’s modulus has been measured for greater temperatures up to 1400°C [J. B. Wachtman Jr. et al. J. American Ceramic Society, 42, p254] and the data show continued modulus linear dependence for the extended temperature range.

INTERROGATORS

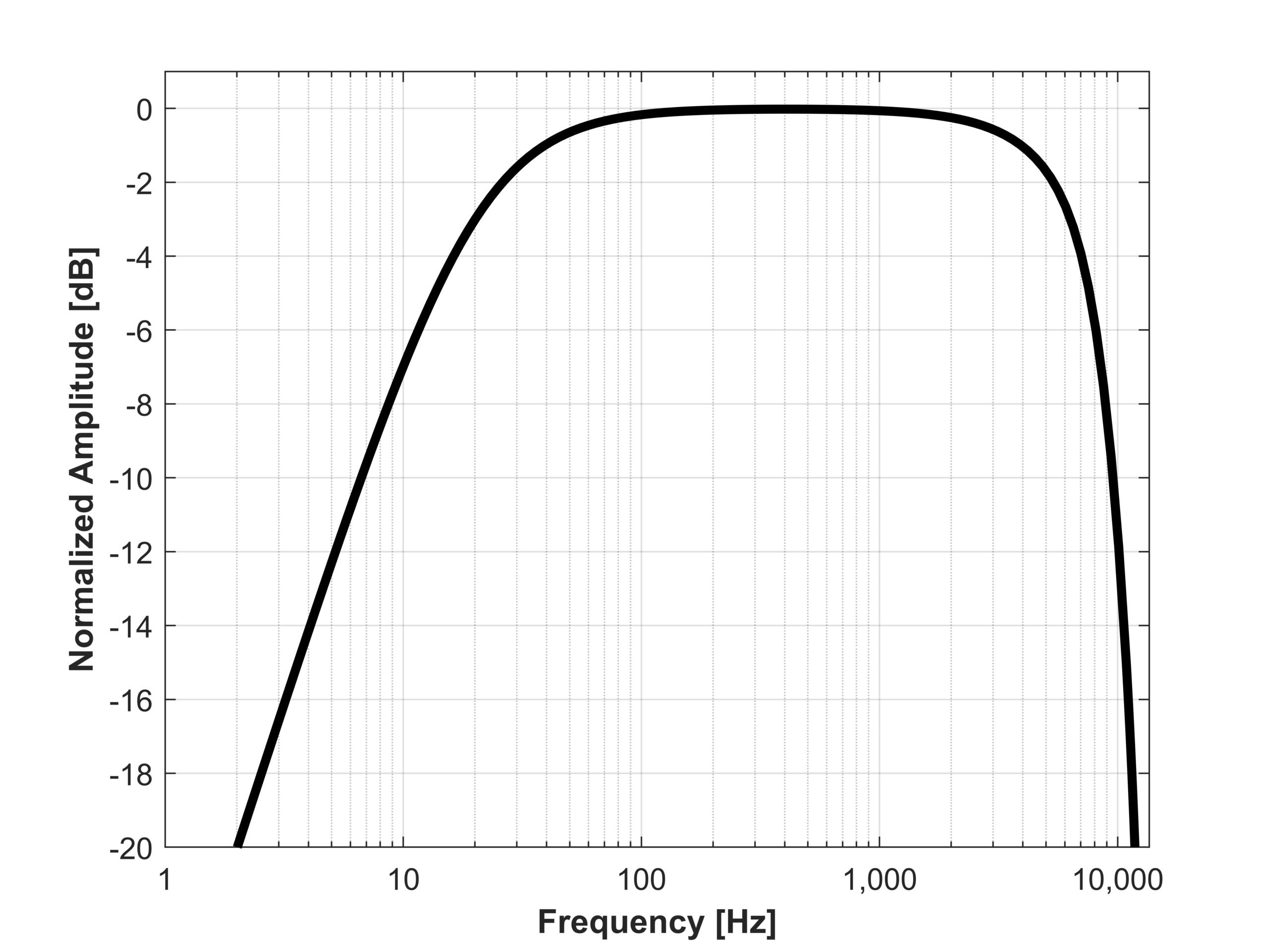

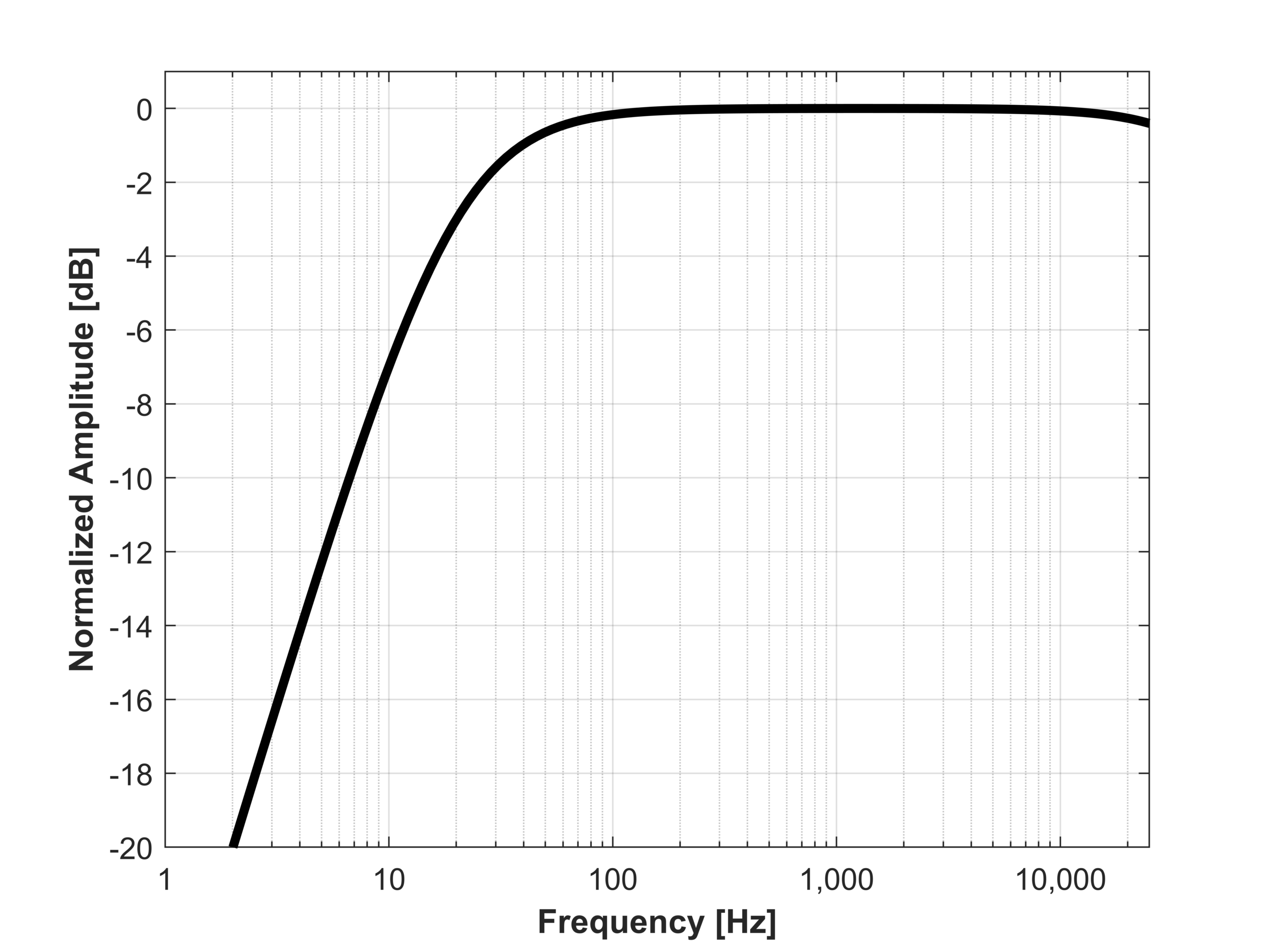

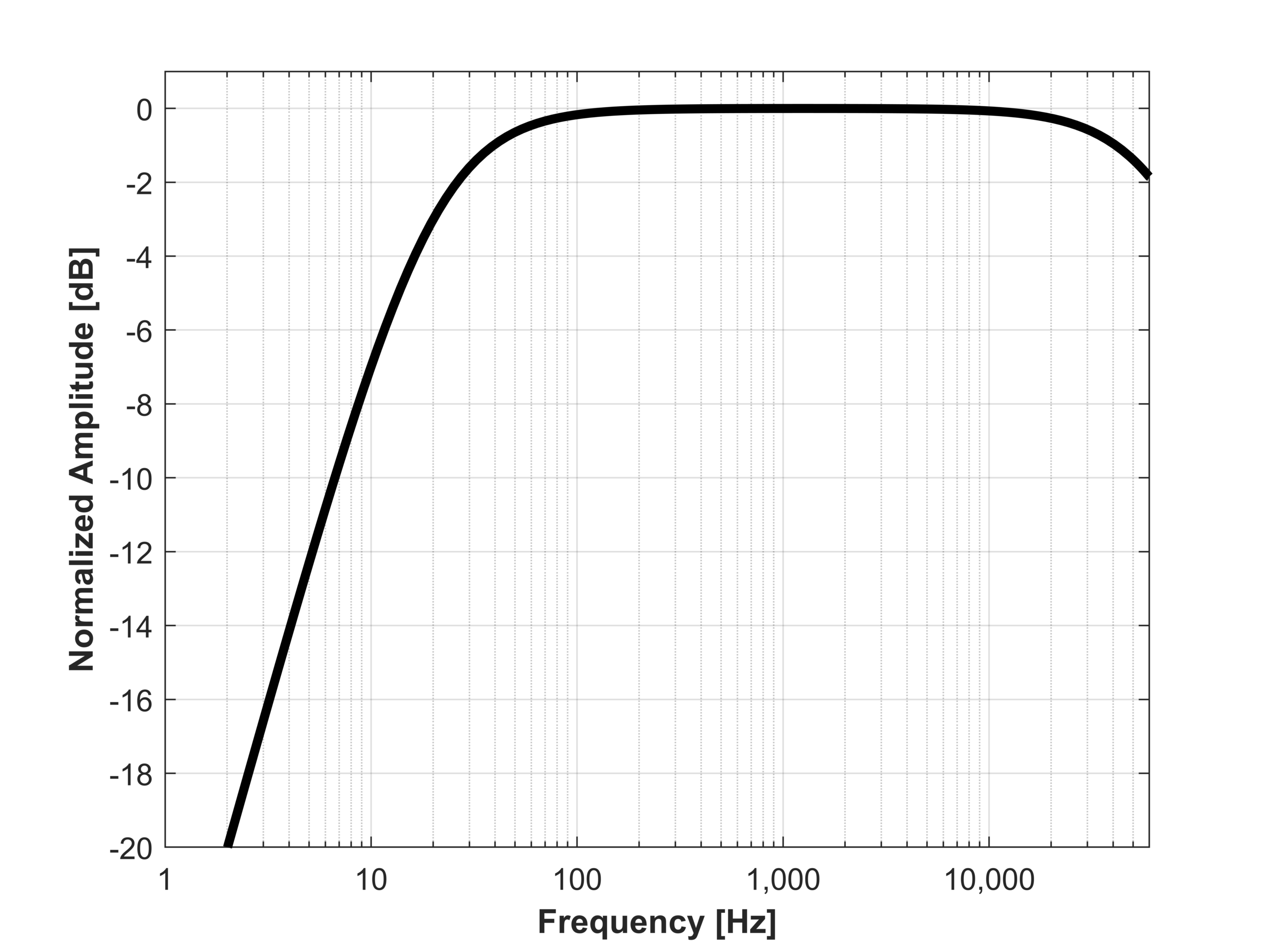

The Fasedyne sensor interrogation instruments are designed to provide flat response over a wide frequency range for high-fidelity broadband dynamic pressure measurement. The frequency responses of each interrogator model are plotted in the figures below.

|  |  |

| Fasedyne-1000 | Fasedyne-2000 | Fasedyne-3000 |

The flat frequency response over the wide frequency range with sharp transitions around the lower and higher cutoffs for each model is achieved by integrated design of analog electronics, digital filters and signal processing algorithms. These frequency responses remain stable across a large dynamic range.