NovaPT®-D Downhole Pressure and Temperature Sensing System Provides Low Signal Drift for Long Distances at up to 300°C

NovaPT-D from Sentek Instrument is a patented pressure and temperature sensing system that offers the highest temperature rating ( up to 300°C) for its application. The monolithic single-crystal sapphire structure-based design makes the sensor intrinsically robust against signal drift, chemical diffusion, and corrosion. The small, 0.75” (19mm) sensor diameter allows the system to be installed in all oil, gas and geothermal wells using most industry-standard downhole deployment methods. In addition, the compact, low-power-consumption Coswave™ interrogator from Sentek Instrument can support up to 16 sensors simultaneously.

Key Features

- High temperature >300°C

- Robust sapphire design

- Long sensing distance

- Compact 0.75” housing diameter

- Multi-channel Coswave interrogator

Ideal For

- Oil, gas and geothermal wells

- Chemical processing systems

- Nuclear reactors

Technical Specifications

Details

| SENSORS | |

| Model | NovaPT-D |

| Maximum Pressure | 14MPa/2kpsi, 55MPa/8kpsi, 131MPa/19kpsi |

| Pressure Precision | 0.002% F.S. |

| Pressure Accuracy | 0.05% F.S. |

| Pressure Drifts | <0.5% F.S. at 200oC per year |

| Temperature Precision | 0.0005oC |

| Temperature Accuracy | 0.5oC |

| Temperature Drifts | <0.2oC at 300oC per year |

| Maximum Temperature | 200oC, 250oC, 300oC, or custom up to 500oC (metal coated optical fiber required) |

| Sampling Rate | 1Hz |

| Optical Fiber | 9µm-core singlemode |

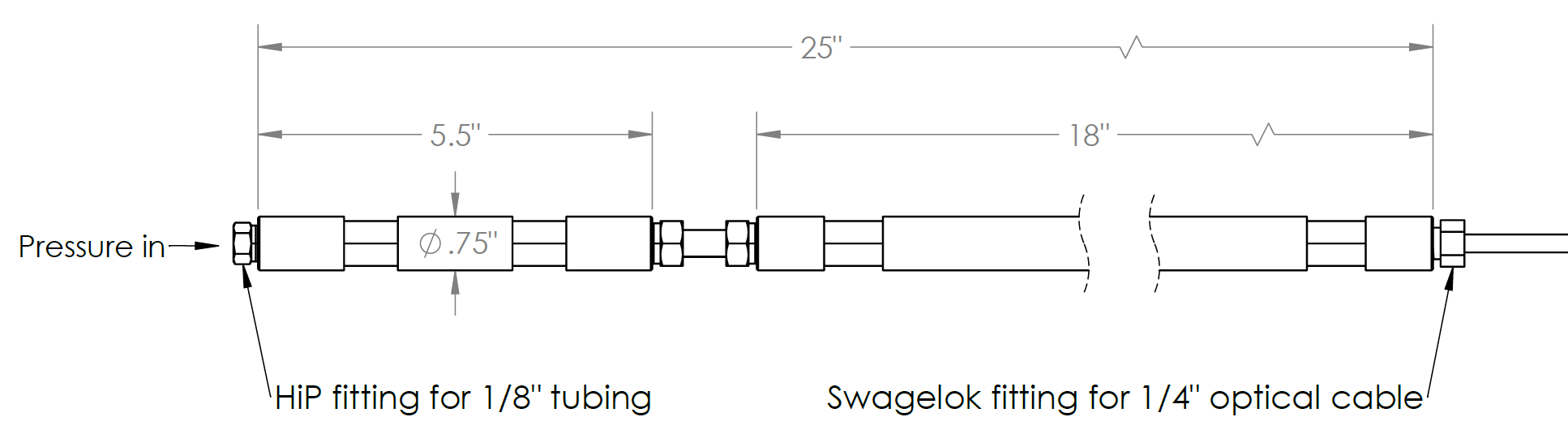

| Sensor Dimensions | 0.75” (diameter) x 25” (length) 0.375” (diameter) x 3” (length) Option |

| SURFACE INTERROGATORS | |

| Model | Coswave |

| Sensor Channels | Up to 16 |

| Optical Fiber | 9µm-core Singlemode |

| Maximum Sensing Distance | 15km |

| Fiber Connector | LC/APC |

| Power Supply and Consumption | 240/110V, 50/60Hz, 5W |

| Dimensions and Weight | 215 x 205 x 55mm; 1.45kg |

| Computer Interface | Ethernet |

| Operating Environment Conditions | 0 to 60oC; 10-95% humidity with no condensation |

Sensor Housing and Cable Consideration

Details

The sensor probe is packaged in a 0.75” diameter housing, which may be made of SS 316L or Alloy 718. Key dimensions of the sensor housing and its connection to a ¼” fiber cable are shown in the drawing below. Using Alloy 718 for the housing main body is recommended for service temperatures greater than 300°C even without the presence of aggressive chemical species such as H2S given its superior resistance against oxidation. Due to the limited pressure rating of the Swagelok fitting, the fiber cable will be connected directly to a ¼” diameter tail of the front 5.5” portion of the sensor housing via direct welding or a customer preferred method for pressure ratings greater than 10,000psi.

A small form factor sensor housing with 0.375” diameter and 3” length is available for special applications where a low physical profile is critical. This housing design permits versatile connections to an optical cable. Typical sensor-to-cable connections include metal compression fittings, laser welding or other special means by customers.

The compact surface interrogator delivers Class I eye-safe light via 9µm-core singlemode optical fiber to the sensor. Pressure and temperature are simultaneously output by the accurate demodulation of the optical signal returned from the sensor. The system is operated at the C-band where silica optical fiber exhibits the minimum transmission loss, permitting the sensing distance to be at least 15km.

Single-crystal sapphire is an extremely stable and robust material both physically and chemically and can operate reliably as a sensor material for temperatures well above 1000°C. The maximum service temperature of the NovaPT™-D sensor is mainly dictated by the fiber coating material. The table below shows commercial fibers with typical coating options for different long-term service temperatures.

| Fiber Coating Material | Maximum Service Temperature (°C) |

| Standard Acrylate | 80 |

| High-Temp Acrylate | 150 |

| Polyimide | 300 |

| Copper | 400 |

| Gold | 600 |